Welcome to Control Waterjet Cutting

We work for many different sectors including precision engineering, aerospace, marine and automotive. We also work for architectural sectors such as sign makers, public art, architectural metal work and sculpture. Waterjet cutting technology is the real alternative to laser cutting, plasma cutting, milling and conventional machining.

Laser cutting, Plasma Cutting, or conventional machining? Consider waterjet cutting. Waterjet cutting technology is the fastest growing major machine tool process in the world. The flexible process either replaces or compliments other technologies such as milling, laser, EDM, plasma and routers. No noxious gases or liquids are used in waterjet cutting, and waterjets do not create hazardous materials or vapours. No heat effected zones or mechanical stresses are left on a waterjet cut surface. It is a truly versatile, productive, cold cutting process.

Aluminium cutting

0.1mm to 160mm thick

Glass cutting

1mm to 30mm thick

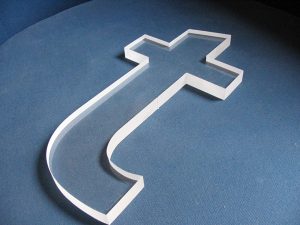

Plastics & Rubber cutting

0.25mm to 160mm thick

Brass & Copper cutting

0.1mm to 160mm thick

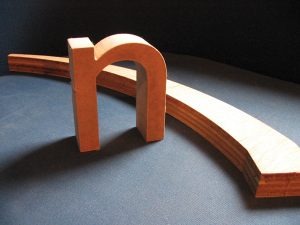

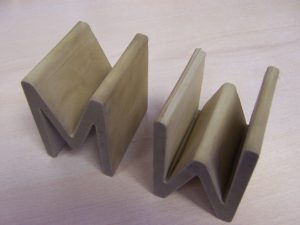

Wood & MDF cutting

1mm to 160mm thick

Stainless & Mild Steel cutting

0.1mm to 160mm thick